Stroje pro mytí, plnění a víčkování lahví

s plnicím výkonem do 1300 lahví za hodinu

Pro mytí, plnění a víčkování lahví v objemech do 1300 lahví za hodinu dodáváme poloautomatické pivovarské strojové myčky, plničky a korunkovačky lahví, které jsou obsluhovány zčásti manuálně, a zčásti je většina úkonů prováděna automaticky a řízená počítačem. Tento mycí a plnicí výkon je dostatečný pro většinu malých pivovarů a cidérek s produkcí do 2000 hl piva nebo cideru za rok.

Pro mytí, plnění a víčkování lahví v objemech do 1300 lahví za hodinu dodáváme poloautomatické pivovarské strojové myčky, plničky a korunkovačky lahví, které jsou obsluhovány zčásti manuálně, a zčásti je většina úkonů prováděna automaticky a řízená počítačem. Tento mycí a plnicí výkon je dostatečný pro většinu malých pivovarů a cidérek s produkcí do 2000 hl piva nebo cideru za rok.

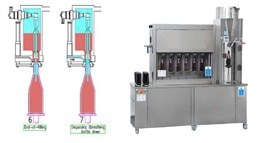

Pro malé pivovary nabízíme poloautomatické plnicí stroje pro operace související s plněním piva, cideru a dalších nápojů do skleněných lahví.

Nabízíme tato zařízení pro plnění piva (cideru, vína) do lahví do 1300 lahví za hodinu :